Sewing Tips

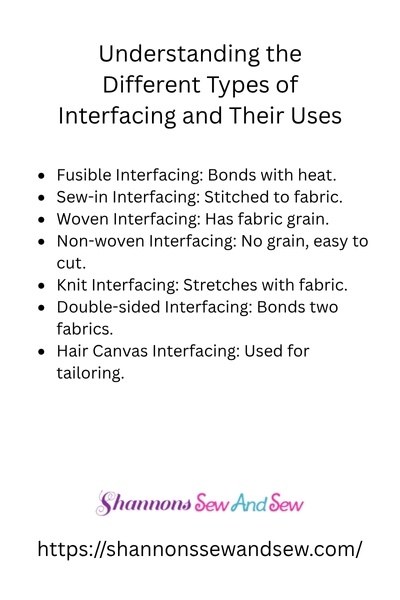

Understanding the Different Types of Interfacing and Their Uses

When it comes to sewing, interfacing is one of those materials that doesn’t always get the spotlight it deserves. You know, it’s the unsung hero that holds your projects together and gives them structure. If you’ve ever wondered what interfacing is, what types exist, or why it’s important, this post is for you. We’re diving into understanding the different types of interfacing and their uses, and trust me, it’s going to be a game-changer for your sewing projects.

Read More About Understanding the Different Types of Interfacing and Their Uses

So, What Exactly Is Interfacing?

Let’s start with the basics. Interfacing is a type of fabric used to reinforce or add structure to your sewing projects. It’s usually applied to areas that need extra support, like collars, cuffs, waistbands, or any part of your garment that could use a little more shape or stiffness. Think of it as the behind-the-scenes helper that makes your projects stand out and hold up to wear and tear.

I’ve used interfacing countless times—whether I was reinforcing a button-down shirt collar or stiffening up the fabric on a tote bag—and let me tell you, I never regret it. It can really take your project to the next level.

More Things to Know About Understanding the Different Types of Interfacing and Their Uses

The Different Types of Interfacing

There are several types of interfacing, and choosing the right one can be a bit confusing if you’re new to it. No worries, though! I’ll break it down for you.

Fusible vs. Non-Fusible Interfacing

First things first, interfacing generally comes in two types: fusible and non-fusible.

- Fusible Interfacing: This type has an adhesive on one side that bonds to your fabric when heat is applied (like with an iron). It’s super convenient and often my go-to choice, especially when I’m in a rush. Fusible interfacing sticks to the fabric without the need for stitching, saving you time.

- Non-Fusible Interfacing: This one doesn’t have an adhesive. Instead, you sew it into your fabric. It’s a little more time-consuming but perfect for delicate fabrics where you don’t want any adhesive residue. If you’ve ever worked with silk or tulle, you’ll know what I mean!

Lightweight vs. Medium Weight vs. Heavyweight Interfacing

Now, let’s talk about the thickness of the interfacing. This is where it gets a little more specific, and you’ll want to pick according to your project’s needs.

- Lightweight Interfacing: This is great for soft fabrics like cotton or linen. It’s perfect for delicate projects like blouses or dresses. It adds structure without making the fabric too stiff, which is exactly what you need when you want something that flows but still holds its shape.

- Medium Weight Interfacing: This is the all-rounder of interfacing. It’s a good choice if you’re working on items like skirts, pants, or jackets. It gives your fabrics more structure without being too stiff. I use it all the time for projects that need a little more body but don’t require heavy-duty support.

- Heavyweight Interfacing: This is for the big stuff. Think of your coats, bags, or tailored jackets. It provides a lot of support and is great for adding shape and durability to fabrics like denim or canvas. I made a canvas tote bag with heavyweight interfacing once, and it made the bag so sturdy, it could practically stand on its own!

Woven vs. Non-Woven Interfacing

Interfacing also comes in woven and non-woven varieties. The difference? It’s all about how the fibers are arranged.

- Woven Interfacing: This is made with fibers that are woven together, like fabric. It has a little bit of stretch and behaves similarly to your fabric, which is great if you’re working with woven fabrics. It’s more stable and provides a little give, making it ideal for shirts and blouses.

- Non-Woven Interfacing: This is made by bonding fibers together, so it’s often stiffer and doesn’t stretch. It’s great for projects where you need more structure, like tote bags or stiff collars.

Specialty Interfacing

Sometimes, you might need a specific type of interfacing to give your project a unique look or function.

- Double-Sided Fusible Interfacing: This type has adhesive on both sides, making it perfect for adding structure to lightweight fabrics without the need for sewing. Think of it as a supercharged version of regular fusible interfacing.

- Bastable Interfacing: This is temporary and ideal when you need something to hold your fabric in place during the sewing process. It’s not for long-term use, but if you’re doing a detailed project, it can be incredibly helpful.

How Do You Choose the Right Interfacing?

Okay, so now you know about the different types of interfacing, but how do you know which one to use for your specific project? Well, it all comes down to the fabric and the type of structure you need.

- For lightweight fabrics, like a delicate cotton blouse, lightweight fusible interfacing is your best bet.

- For medium fabrics, like a pair of jeans or a skirt, medium weight interfacing will give you that nice balance of structure and flexibility.

- And for heavy-duty projects, like outerwear or bags, go with a heavyweight fusible interfacing or even a non-fusible option if you want to sew it in.

Elevate Your Sewing With Smart Interfacing Choices

So, there you have it! Understanding the different types of interfacing and their uses is all about knowing your fabric and your project’s needs. Whether you’re a seasoned pro or a beginner, choosing the right interfacing will make a huge difference in the final outcome of your sewing projects. It’s one of those little details that doesn’t get enough attention, but once you start using it, you’ll wonder how you ever sewed without it.

And trust me, you’ll feel pretty proud when you see how professional your project turns out—thanks to a little interfacing magic.