Supplies And Equipment

Threading A Sewing Machine The Easy Way

Threading a sewing machine is one of the first things you have to learn as a seamstress. If you’ve never used a sewing machine before, this can seem daunting, and even put you off for good.

As a matter of fact, all you need to do is learn and follow the right steps. On older machines, the first thing to do is to disengage the needle.

This would allow you to wind the bobbin without the needle flailing like crazy during this operation. Newer machines have a special wheel that disengages the needle automatically.

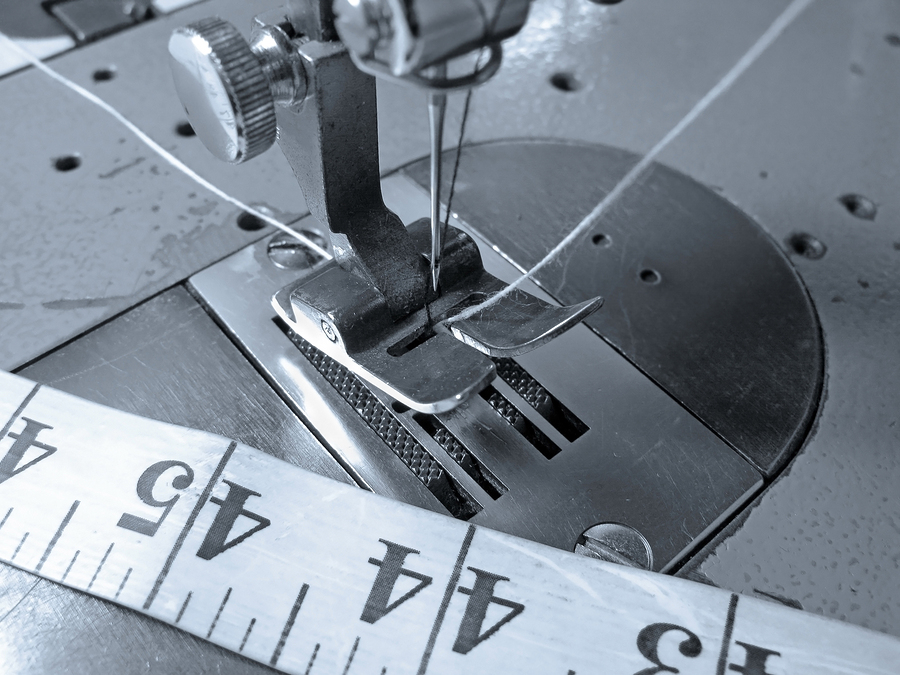

Next, you have to get the bobbin out of its special compartment under the sewing needle. The bobbin is a small spool that needs to be prepared with a thread before you can sew anything.

Once you’ve got the spool out, place it on the top of the sewing machine, on its special pin. Wind the thread around the bobbin a little, and then set everything in place for the automatic threading.

If you don’t know how to do it, you can either check out the diagram that came with your machine or search for help online.

Anyway, the winding tension disc on the top of the sewing machine is easy to see, so all you need to do is make sure you position the spool in such a way that the thread goes counter-clockwise.

Before pushing the pedal to start the automatic threading, you should slide the bobbin pin over to lock the spool in place. Try to apply an even pressure on the pedal, and keep it constant until the bobbin is full.

By this moment, the winder should automatically stop. Now it’s time to reengage the needle and to place the bobbin back into its special chamber.

Before inserting the spool, you have to unwind a few inches of thread, as it’s going to help you later on, in the process. Dropping the bobbin into place is easy, as it can only go the right way, thanks to a special cutout that prevents insertion errors.

Close the cover when you are done. Next, you need to pull the upper thread though the machine, closely following the diagram printed somewhere on its body.

You’ll have to pay attention to all tension discs, as you shouldn’t miss any of them. They have the role of regulating the tension in the thread during the sewing process.

Once you are finished, you have to thread the needle through its eye. The last thing to do is to expose the bobbin thread.

For this, you have to spin the big wheel on the right side of the machine. A few spins should be enough to make the needle advance into the bottom compartment to grab the end of the bobbin thread and bring it on the plate.

This is the easy way of threading a sewing machine. You may find it a bit tricky in the beginning, but you are surely going to become familiar with all the steps after a few trials.